The above picture shows the cylinders with the hoses prepped. The hose ran from the tank (co2) and regulators through a valve that controlled the system then to each caster in a row. Since the shift happened at intermission we determined that the casters didn't have to fire at the same time so we ran the hose sequentially. The first three casters used Tee push in fittings (threaded to fit into the cylinder), and the last was a straight fitting. The air pressure was open, the regulator was adjusted to 80psi, and the valve was opened. The cylinders pushed the casters out, lifting the platform. The shift was performed. The air was turned off, the valve opened to exhaust the system and the weight of the platform pushed the casters back into the cylinders, setting the frame securely on the floor.

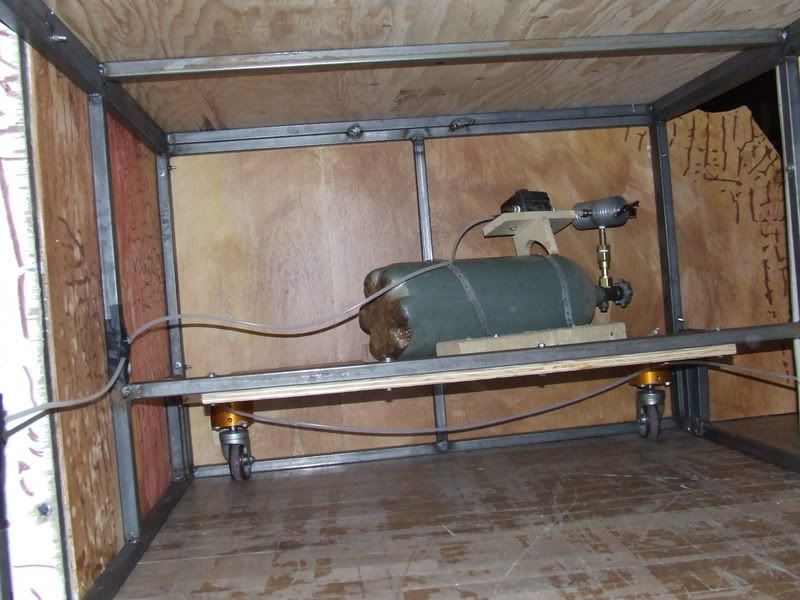

The above picture shows the cylinders with the hoses prepped. The hose ran from the tank (co2) and regulators through a valve that controlled the system then to each caster in a row. Since the shift happened at intermission we determined that the casters didn't have to fire at the same time so we ran the hose sequentially. The first three casters used Tee push in fittings (threaded to fit into the cylinder), and the last was a straight fitting. The air pressure was open, the regulator was adjusted to 80psi, and the valve was opened. The cylinders pushed the casters out, lifting the platform. The shift was performed. The air was turned off, the valve opened to exhaust the system and the weight of the platform pushed the casters back into the cylinders, setting the frame securely on the floor.  Above: The system set up in the shop.

Above: The system set up in the shop. Above: the platform with the system in process of installation.

Above: the platform with the system in process of installation. Above: interior view of installed system

Above: interior view of installed system

Above: exterior of platform with flats attached.

No comments:

Post a Comment